Versatile solutions with clips: clever fastening for different requirements

Clips are an important element when it comes to secure and reliable fastening systems. Gudo AG has developed various clips that are suitable for different purposes. This article gives you an overview of the areas of application for clips and the models we offer.

How do clips work and what are they used for?

Clips are used to hold cables, toothed belts or textile straps securely in place. The clip clamps the cable, belt or strap. This also allows the length to be changed flexibly.

The clips from Gudo AG are used in the following products, among others:

- Shoes

- Helmets

- Orthoses

Thanks to their high-quality workmanship, they are reliable components that guarantee maximum safety.

The combination of clip and Timing belt or textile strap ensures that shoes have a firm hold on the foot. This is particularly important for ski and safety shoes. In both cases, it is extremely important that the shoes sit firmly on the feet. If this is not the case, it can be potentially dangerous.

Helmets also need to fit securely, as otherwise they can lead to hazardous situations. This applies to both bicycle helmets and safety helmets worn by police officers or firefighters, for example.

Orthoses must also sit firmly on the part of the body that they are intended to support - such as the knee or Ankle joint. This is the only way to effectively relieve the joint. The combination of clip and strap or band makes it possible to fix the orthosis in place. It therefore fulfills its purpose perfectly.

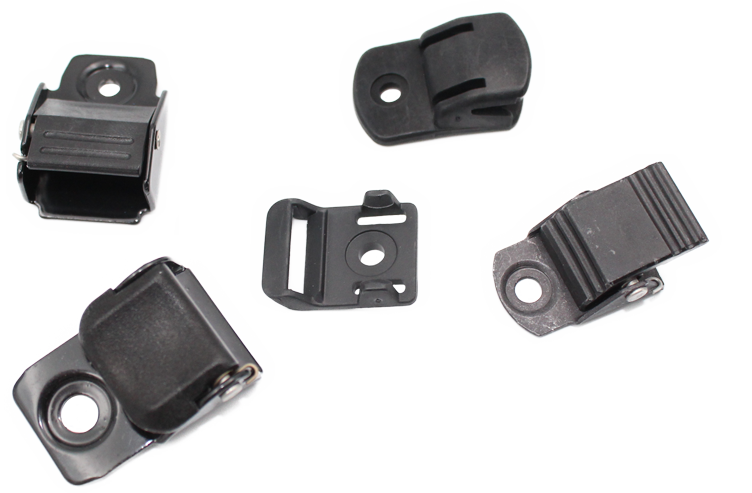

Which clips are in the Gudo AG portfolio?

Our clips differ in terms of the following criteria:

- Design

- Width of the attachable straps or belts

- Material

Below we provide you with a brief overview of our clips.

Clips with a width of 15 millimeters

The Clip 52 is our only model that is suitable for 15 millimeter wide straps and belts. It is made of plastic and sits on a steel plate. To release the belt tension, all you need to do is apply light pressure to the belt.

Clips with a width of 18 millimeters

We offer three different types of clips for 18 millimeter wide belts and straps. The model Quick Fix has a very simple design and is therefore very easy to handle. It is used with a toothed belt that can be simply retracted and clicked into place. The clip is also suitable for belts with a width of 22 millimeters.

The Clip 82 is available with a straight or curved steel base plate. There is a spring-loaded toothed piece on the plate. The design makes it possible to fix an 18 millimeter wide toothed belt. To release it, simply press lightly on the clip.

At the Clip 85/86 is a versatile model for different applications. It is just as suitable for shoes as it is for helmets.

Clips with a width of 22 millimeters

Our range offers the largest selection for 22 millimeter wide belts and straps. These include, for example, the Clip 13. It consists of a steel base plate fitted with a plastic tooth piece. This holds the toothed belt in place. When the clip is lifted, the belt unlocks.

With a curved steel plate, the Clip 22 equipped. This special design feature opens up a wide range of possible uses. If you prefer a straight plastic top, then choose the Clip 2K.

Specially designed for use with textile straps, the Clip TX. It is available with a U-shaped steel base plate on request.

Matching timing belts for our clips

We not only supply you with clips, but also the matching Timing belt. With widths of 15, 18 and 22 millimeters, they are optimally compatible with our clips.

The clip 52 matches the Toothed belt UV15-F. It is 15 millimeters wide, 140 millimeters long and equipped with a slot.

Timing belts with different designs are compatible with our clips, which are designed for a width of 18 millimetres. For example, the 4 x 20 millimeter slot of the Toothed belt UV 18-S. We offer it in lengths of 85 and 155 millimeters. With one hole, the Toothed belt UV18-R equipped. The strap is available in various lengths.

For example, our clips for 22 millimeter wide timing belts fit the model UV22-I. There are two holes in its end lug. This ensures a particularly secure fastening. The strap is 225 millimetres long.

Product development and production with Gudo AG

As experts in the development and manufacture of closure systems, we have a wealth of know-how and experience. We are also happy to use our knowledge and skills to assist you with product development. From planning to series production and assembly, you can rely on our services leave.

Do you have an idea for a product that you would like to put into practice? Do you need a competent partner? Then please contact Gudo AG.

Product development

The Development of a product forms the basis for a successful market launch and lasting success. It is not only the design and functionality of the product that are important. It is just as important to take economic aspects into account. The aim is to keep the costs of development and production as low as possible.

Your cooperation with Gudo AG in product development always begins with a comprehensive consultation. We ask you to explain in detail how you envision the planned product. We assess the project realistically, check its feasibility and provide practical tips for improvement.

Prototyping is an important step that we take when developing new products. This is the term used to describe the production of early versions of the planned product. We produce prototypes that are fully functional. This allows them to be put through their paces. If errors or problems are identified, they can be rectified at an early stage.

Production and assembly

Successful product development is usually followed by the Production to. Our factory in Lupfig has various state-of-the-art machines available for this purpose. This enables us to use different production methods. Our machinery includes the following machines:

- Injection molding machines

- 3D printer

- Punching tools

The manufacturing process with these machines is efficient, fast and cost-effective.

Depending on the product, a Mounting necessary. You can also commission us to do this for you. We carry out this task in our assembly systems - regardless of the production quantity.

Function and quality testing

We know that consistently high quality is essential in series production. We have therefore introduced various measures to ensure this. For example, our employees regularly take part in training and further education. This enables them to expand their skills and knowledge, which benefits their work enormously.

We also carry out periodic quality checks on our productions. Any errors are identified and can be eliminated. Our aim with every production is to remain completely error-free. If you have any questions about our clips, other products from our portfolio or our services, please do not hesitate to contact us. For your message you can our contact form use. You can also reach us by e-mail and telephone.