The optimal choice of timing belt: How to find the right model

Timing belts offer a reliable way of transmitting power. This can be put to optimum use when fastening various items of clothing. Safety shoes, for example, can be fastened precisely to the foot thanks to toothed belts.

Gudo AG offers a range of Timing belt for various areas of application. In this article, we will inform you about what characterizes timing belts and which models you can obtain from us.

What are timing belts?

A timing belt is a belt that is provided with a profile. This distinguishes it from a flat belt, which has no profile. The counterpart to the timing belt is the pulleys over which it runs. This makes the belt very efficient at transmitting power.

What are timing belts used for?

An important area of application for timing belts is the clothing industry. Whenever a shoe or helmet needs a particularly strong hold, you can rely on the belts. The timing belts manufactured and offered by Gudo AG are used in this area.

Our timing belts can be used for the following products, for example:

- Safety shoes

- Ski boots

- Gas masks

- Bicycle and luggage racks for cars

- Bicycle frame holder

For all these objects, it is essential that they have a secure fit. Safety shoes are often worn in situations where there is a risk of injury - for example in factories or during fire or police operations. In these situations, it would be fatal if the shoes had no grip on the feet. The same applies to gas masks.

Ski boots also need a firm grip on the foot. Under no circumstances should they come loose on the piste or even slip off the foot. This would endanger the wearer and possibly other people as well. put in great danger.

There must also be no problems when transporting bikes by car. The carrier must be securely fastened to the car, just like the bikes to the carrier. A frame holder is used to secure several bikes together. High-quality toothed belts prevent the connection from loosening during the journey and thereby creating a hazard.

Other products that can be fitted with the belts are also conceivable. We offer various models of timing belts. You are sure to find the right one for your specific application.

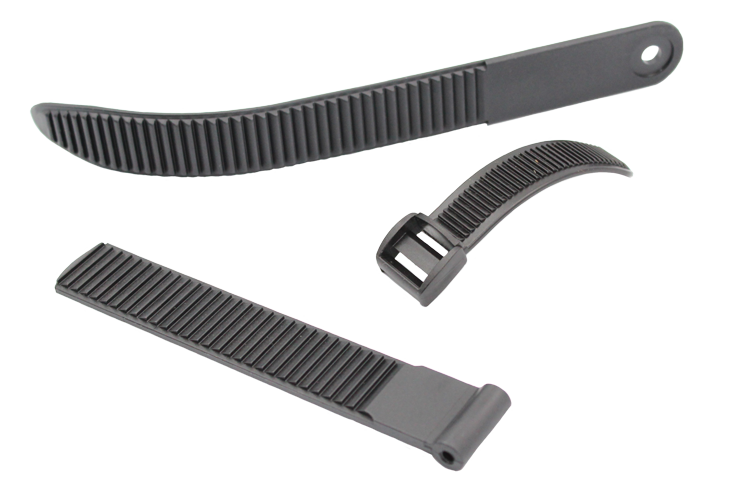

The timing belts in the Gudo AG range

We manufacture timing belts in the following widths:

- 15 millimeters

- 18 millimeter

- 22 millimeter

The only model with a width of 15 centimeters in our portfolio is UV15-F. The strap has a length of 140 millimeters. It can be looped into the existing slot, or alternatively it can be sewn on.

Various timing belts from our range have a width of 18 millimetres. They differ in terms of their length and the way they are attached. One of the shortest variants is UV18-S with a length of 85 millimeters. However, a version with a length of 155 millimeters is also available. The slot is 20 by 4 millimeters.

The Timing belt UM18-K is equipped with two slits. It is used in combination with a textile strap that is fed through the slots. The strap is therefore curved. It has a length of 90 millimeters.

Some belts with a width of 18 millimetres are designed to be bolted or riveted. They have a hole at one end for this purpose. With the model UV18-R the bore can have a diameter of 4.5 or 5.2 millimeters. The surrounding countersink can be 10 or 10.5 millimeters in size. Different lengths from 75 to 300 millimeters are available.

The belt has two holes UV18-I on. They are located in an end lug and each have a diameter of 4 millimetres and a countersink of 10 millimetres. There is a choice of lengths between 100, 125, 160 and 200 millimetres.

Our timing belts with a width of 22 millimetres are also available in different versions. With a 6.5 millimeter hole, the model UV22-R provided. The belt is available in various lengths from 125 to 400 millimetres.

The belt has a curved shape UM22-R on. This makes it easier to use for clamping round bodies.

Toothed belts in combination with tension locks

Some of our timing belts are designed for use in combination with a tension lock. These include the model RVS. It is 22 millimetres wide and has a 23 millimetre wide end bar. It contains a cross hole with a diameter of 3.2 millimetres. The belt is available in lengths of 125, 200 and 275 millimetres.

To match the RVS belt, we offer the RVS/RVS-A tension lock on. It is compatible with the dimensions of the belt and enables almost infinitely variable presetting thanks to its swivel bracket. It is also equipped with a snap function. This makes it difficult to open the buckle unintentionally.

The Timing belt RVB is also designed for use with a tension fastener. With a width of 22 millimetres, the belt is equipped with a 27 millimetre wide end bar. The cross hole in it has a diameter of 3.2 millimeters. The available versions are 150, 200 and 275 millimetres long.

The RVB belt fits the Clamping fastener of the same name. It has a round bar for almost infinitely variable presetting.

Gudo AG: Experts in the design and manufacture of fastening systems

Gudo AG is your competent partner when it comes to fastening systems. In addition to toothed belts and tension fasteners, our production facility also manufactures twist and ratchet fasteners and clips. We also manufacture special products such as hoof boots, headsets with protective covers and police belts.

We are also happy to help our customers when it comes to developing new products. We take on key tasks at all stages on the way to a finished product that is suitable for mass production. This begins with comprehensive advice, during which you benefit from our experience and expertise.

We discuss with you whether the planned design can be implemented and whether the product will be profitable. We also provide you with valuable information that refines your perspective on the product.

In addition to the Development of the design, we also keep an eye on the engineering. The aim is to ensure that subsequent production runs as efficiently as possible right from the planning phase.

Another service we offer in product development is prototyping. We produce early versions of the planned product. These prototypes are fully functional and ready for use and can therefore be tested extensively. This allows us to identify potential weaknesses that can be eliminated and avoided in the next prototype.

We are also happy to manufacture the finished product ready for series production in our production facility in Lupfig. Here we use various machines that enable us to use different manufacturing processes. Whether injection molding machines, 3D printers or punching tools: Our machine park is sure to have the right equipment for the intended production.

Also for the Mounting if required. Thanks to our flexible assembly systems, we carry out this work cost-effectively and on time. This applies to both large production quantities and small batches.

Contact Gudo AG

Do you have any questions about our timing belts or other products from our portfolio? Or are you interested in our services in the development and manufacture of products? Please feel free to send us a message via our contact form.